Electric power can be transmitted or distributed either by overhead system or by underground cable. Cables are mainly designed as per requirement. Power cables are mainly used for power transmission and distribution purpose.

It is an assembly of one or more individually insulated electrical conductors, usually held together with an overall sheath. The assembly is used for transmission and distribution of electrical power.

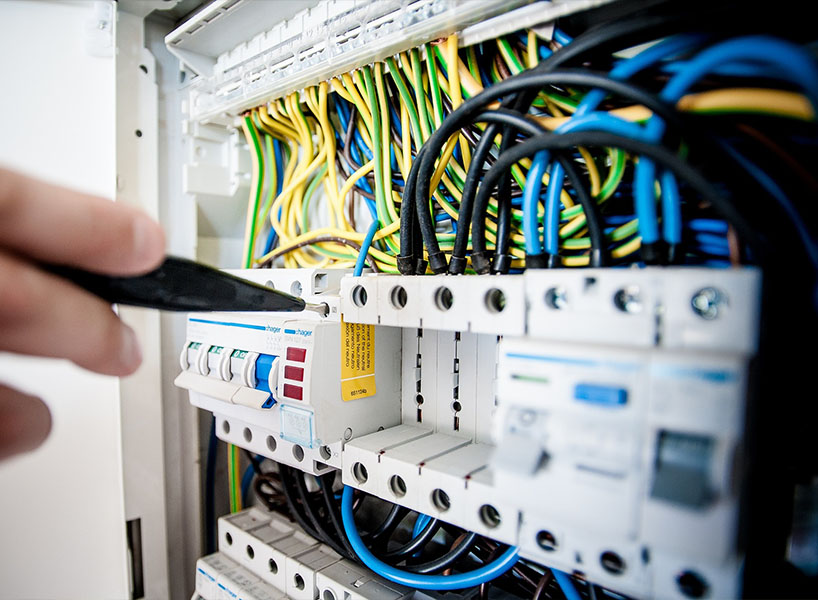

Electrical power cables may be installed as permanent wiring within buildings, buried in the ground and run overhead or exposed. Flexible power cables are used for portable devices, mobile tools and machinery.

These are designed and manufactured as per voltage, current to be carried, operating maximum temperature and purpose of applications desired by customer. For mining, we give extra mechanical strength to cable with double armoring.

For wind power plant customers generally require flexible and UV protected cable with mechanical tough sheath so we design as per their requirement. The underground cables have several advantages such as less liable to damage through storms, lightning, low maintenance cost, less chances of faults, smaller voltage drop and better general appearance.

Current carrying capacity is an important aspect is the selection of the optimum size of conductor. Voltage drop and short rating is also very important aspect to select the economical and optimum size of conductor.

The safe current carrying capacity of an underground cable is determined by the maximum permissible temperature rise. The cause of temperature rise is the losses that occur in a cable which appear as heat.

The allowable maximum voltage drops from source to load is another aspect of power cable conductor design. As per Ohm’s law, V = IR. The first is the choice of material used for the wire.

Copper is a better conductor than the first is the choice of material used for the wire. Copper is a better conductor than and will have less voltage drop than aluminum for a given length and wire size.

Wire size is another important factor in determining voltage drop. Larger wire sizes (those with a greater diameter) will have less voltage drop than smaller wire sizes of the same length.

In American wire gauge, every 6 gauge decrease gives a doubling of the wire diameter, and every 3 gauge decrease doubles the wire cross sectional area. In the Metric Gauge scale, the gauge is 10 times the diameter in millimeters, so a 50 gauge metric wire would be 5 mm in diameter.

© Copyright OCI Cable India by Vijatshi Software Pvt Ltd..